Why electric motors fail in industrial applications and how to prevent it

With their high reliability, we sometimes forget why electric motors fail and how avoiding this needs some simple TLC. Focussing on this important issue, ABB has an interactive online booklet examining the main reasons why electric motors fail and how to prevent it.

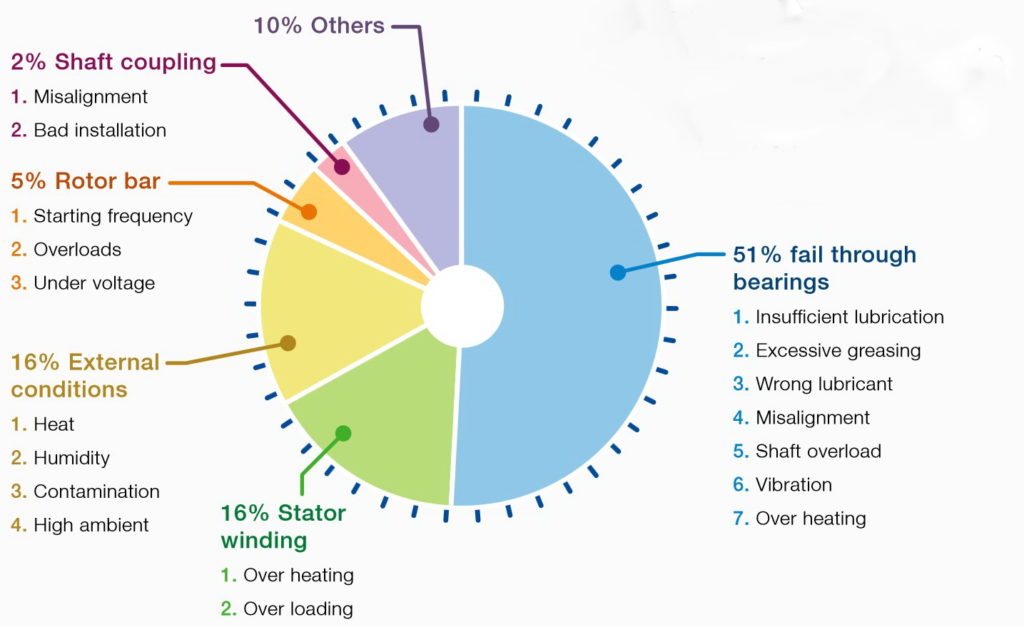

They also identify the six main failure categories, and of these, bearing failure accounts for over half (51%). Helpfully, each category is further broken down by principle cause, along with suggested preventative actions.

In general, motor failure is not due to age or operating hours alone, but to one of the main categories. ABB identifies these along with examples of suggested actions. Although the focus is on ABB motors, most comments apply to industrial electric motors: if in doubt, read the manual.

Why electric motors fail

51% Bearing failures

| Reason | Suggested actions |

| Insufficient greasing. | Re-greaseable bearings need regular maintenance every 2000 hours or three months |

| Excessive greasing | Incorrect greasing procedure may damage seals |

| Incorrect lubricant | Due to incorrect lubricant or mixing of greases |

| Misalignment | Due to incorrect alignment of motor and load-many causes |

| Shaft overload | Indicated by excess wear and also usage of drive belts |

| Vibration | Chiefly problems with shaft or housing vibration |

| Overheating | Ensure correct grease for high temperature applications |

16% Stator winding failure

| Overheating | Resulting from excessive-visually inspect windings |

| Overloading | Consider thermistor protection |

16% External environmental conditions

| Motor operating temperature | Regularly checks of cooling system |

| Humidity and environment | Corrosion from excessive ambient temperature/humidity and moisture |

| Contamination | Due to foreign particles or wrong IP |

| High ambient | Motor not derated for high temperature |

5% Rotor bar

| Excessive starting frequency | Leading to thermal stress or inertial fractures |

| Overloads | Locked rotor or stall conditions |

| Undervoltage | Low voltage use increases running current |

2% Shaft coupling

| Misalignment | Frequently due to incorrect mounting. Use laser alignment |

| Poor installation | Alignment of incorrect choice of coupling |

The remaining 10% of failures are due to a combination of the above, operational misuse, lack of experience or vandalism.

The appropriate use of ABB variable speed drives can mitigate many of these problems as they also operate as a protective device as well as their soft-start capability.

Recent blog posts