VSD for wind/unwind applications

Mitsubishi’s wind/unwind inverter provides control technology for continuous roll-to-roll applications. It is for the processing of a web (sheet of a paper, film, or other material) from the unwinding roll to the winding roll. Moreover, it features stable winding and unwinding performance, and ease of start-up and adjustment.

The FR-A800-R2R is a dedicated roll-to-roll drive offering dedicated functions. It includes automatic winding diameter calculations, automatic dancer speed control, and sensorless torque control. It performs fast, smooth, and accurate winding/unwinding applications with precise tension feedback. Thus delivering stable and precise control in VSD wind/unwind applications.

These complex functions do not need additional sequence or motion control programming. The FR-A800-R2R inverter’s built-in PLC eliminates the need for a separate controller. It offers easy-to-use parameterisation to set and enhance functions. Markedly, it enable users without advanced tension control knowledge to control winding/unwinding applications.

VSD wind/unwind applications

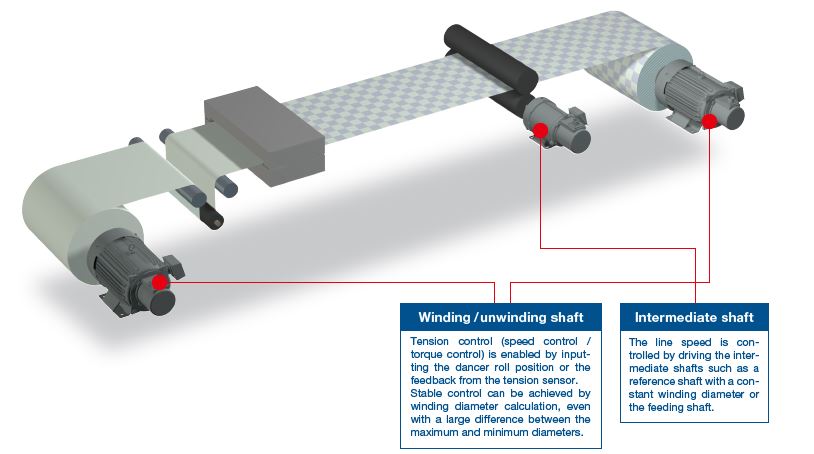

Complex position control of the dancer roll is set using inverter parameters alone. A PID control function keeps the dancer roll position and eliminates hunting. Thus, ensuring efficient wind/unwinding applications. PID control uses feedback from the dedicated dancer roll position or from the tension sensor. Stable control is possible in combination with the winding diameter calculation. In addition, the inverter automatically sets the optimum PI gain to reduce system start-up time,

Winding diameter compensation function

Controlling speed and torque allow changes in the diameter of the winding and unwinding shafts during operation. The present winding diameter of the winding unwinding shaft derives from the actual line speed or the actual motor speed to ensure quick and easy system setup.

Tension control (inertia compensation/mechanical loss compensation)

Torque required for acceleration/deceleration and the mechanical loss compensation torque are controlled. As a result, they keep material tension constant and reduces wrinkling or deformations within the roll.

Speed Control and Gain Compensation –

PID control utilises the feedback from the detected dancer roll position or feedback from the tension sensor. Stable control derives in combination with the winding diameter calculation. What’s more, adjusting the speed control proportional gain relative to winding diameter response remains constant.

Tension Sensor Feedback Torque Control –

The control function raises accuracy of the tension control using feedback from the tension detector. This compensates for mechanical loss due friction on the dancer role and winding unwinding shaft. Compensating also for errors with the winding diameter or mechanical losses of aging or temperature. Finally, wind/unwind dedicated inverter models from 999 Mitsubishi are suitable for printing, splitting, coasting and twisting applications,

Recent blog posts